-

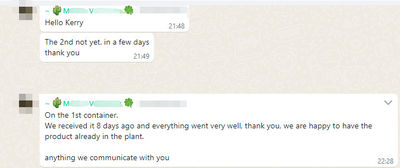

氏「私達は前にそれを8日受け取り、すべては非常によく感謝する私達によってが持って幸せである行った 植物のプロダクト既に。私達があなたと」伝える何でも

氏「私達は前にそれを8日受け取り、すべては非常によく感謝する私達によってが持って幸せである行った 植物のプロダクト既に。私達があなたと」伝える何でも -

氏「こんにちはケリー、私達はパネルのそれ以上のテストをし、結果と幸せ」である。

氏「こんにちはケリー、私達はパネルのそれ以上のテストをし、結果と幸せ」である。 -

ミセスとても満足しています. 良い製品です. 迅速な送料とすべてが非常にうまく行きました.

ミセスとても満足しています. 良い製品です. 迅速な送料とすべてが非常にうまく行きました.

大スパン高品質の鉄骨構造プレハブ倉庫建設プレハブワークショップビルのモダンなデザイン高速インストール

| 起源の場所 | 河北省、中国 |

|---|---|

| ブランド名 | BAODU |

| 証明 | ISO9001,CE |

| モデル番号 | 鉄鋼倉庫 |

| 文書 | 製品説明書 PDF |

| 最小注文数量 | Discussible |

| 価格 | Reasonable |

| パッケージの詳細 | 一般的に鉄骨造の場合、商品が壊れないように鉄骨パッキンを使用します。サンドイッチパネル、カラー鋼板には樹脂パッキンを使用しております。クライアントが特別な梱包を必要とする場合は、要件に従って行います。 |

| 受渡し時間 | 15-21Days |

| 支払条件 | L/C、D/A、D/P、T/T、ウェスタンユニオン、マネーグラム |

| 供給の能力 | 月額10000平方メートル/平方メートル |

| 製品名 | 大スパン高品質の鉄骨構造プレハブ倉庫建設プレハブワークショップビルのモダンなデザイン高速インストール | キーワード | 鉄骨構造の建物の倉庫 |

|---|---|---|---|

| アフターサービス | オンラインテクニカルサポート | 材料 | Q235/Q345スチール |

| 構造 | 溶接された鋼構造フレーム | 屋根の被覆 | EPS/岩毛/ガラス繊維の羊毛/PUサンドイッチパネルまたは鋼板 |

| 加工サービス | 曲げ、溶接、デコイ、切断、打ち抜き | 製品名 | プリファブ 製鋼倉庫 |

| サイズ | 顧客の要求に応じて | インストールガイド | インストール図面とビデオ |

| 一生 | 50年以上 | インストール時間 | 2~4週間 |

| 可搬性 | トラックや船で簡単に輸送可能 | ||

| ハイライト | 大幅なスパン製鋼倉庫,工房の建築 現代のデザイン,スチール構造の倉庫を迅速に設置する |

||

ハイ,親愛なる友よ, 鉄筋構造の建物は,あなたの特定の要求を満たすためにカスタム設計されていることを注意してください. 私たちの例の写真があなたのビジョンに一致しない場合は,心配しないでください.20年以上の経験を持つ私たちのチームは,正確なデザインを作成します建物のデータや図面に基づいて 提供します

- コラム:垂直支柱のための熱巻きH切断鋼または溶接された箱切断

- 梁:柱間を横切るH段またはI段の梁

- 屋根の支柱/支柱: 屋根の覆いを支える支柱またはC/Z切断の支柱

- 壁帯: 壁壁を支える水平の部品

- 屋根や壁の覆い: 波紋鋼板,隔熱サンドイッチパネル

- ブラシングシステム: 風や地震に対する安定性のための横向鋼棒やケーブル

高強度なボルトと溶接は 堅牢で統合された構造の接続を保証します

カスタマイズされた引数とデザインのために,次の情報を提供してください.

- 場所:建物が建設される国と都市

- サイズ:長さ × 幅 × エイブの高さ (mm)

- 風の負荷:最大風速 (kn/m2,km/hまたはm/s)

- 雪の負荷:最大雪の高さ (kn/m2, mm) と温度範囲

- 耐震性必要な地震レベル

- ブロックウォール:必要な高さ (1.2m,1.5m,または他の)

- 熱隔離:EPS,ガラス繊維の羊毛,岩毛,PUサンドイッチパネル,金属シート

- ドア:量と寸法 (幅 × 高さ mm)

- ウィンドウ:量と寸法 (幅 × 高さ mm)

- クレーン:量,最大起重量 (トン) と起重高度 (m)

- 大幅なスパンデザイン:倉庫と大型機器のためのオープンな内部空間

- スピード 建設:プリファブリックコンポーネントは 製造サイクルを短縮する

- 軽量:基礎の負荷と建設コストの削減

- 優れた地震性能:極端な条件下での優れた安全性

- 耐久性:腐食防止は,長寿を保証する

- 高い柔軟性異なる用途のデザインをカスタマイズできる

- 環境 に 優しい:リサイクル可能な鋼は持続可能性と一致する

- 低保守:長期的に低コストで シンプルなメンテナンス

- デザイン&エンジニアリング:負荷計算を含む詳細な建築・構造図

- 製造:工場環境での切断,溶接,掘削部品

- サイトの準備と基礎:掘削とコンクリートの基礎の注入

- 勃起:主要鋼筋の枠と二次部品の組立

- 収納物:屋根 や 壁 の 敷き布団 や 隔熱 システム の 設置

- 仕上げ:ドア,窓,換気,内装 の 追加

製造済み 製鉄 倉庫 の 部品 は,輸送 の 間 に 損傷 を 防止 する ため,安全 な 包装 と パレット化 で 慎重 に 詰め られ て い ます.簡単に 設置 する ため に 詳細 な 組み立て 指示 が 付属 し て い ます.

私たちは,目的地と注文量によって異なるコストで世界中に送料を提供しています. 送料料金と配達時間表については,当社の顧客サービスに連絡してください.

Baodu International Advanced Construction Material Co., Ltdは,2010年に設立され,北京の事務所と,中国の河北の工場を拠点に,包括的なデザイナー,メーカー,サプライヤー,産業用騒音処理の輸出業者鋼鉄構造やサンドイッチパネル,プリファブハウス

年間生産能力には 6百万平方メートルの音響サンドイッチパネル, 10万トンの鉄鋼構造物,世界 30 以上の 国 で 奉仕 し て い ます.

専門的な設計チームには 5人のシニアエンジニア 20人のエンジニア 35人の技術者がいて 10年以上の経験があります建築士資格,CE認証,そしてロシアのGOST認証

有名なプロジェクトは,中国の60周年軍事パレード村,北京ダキシン国際空港,ター・パキスタン石炭火力発電所,ハシアン・ドバイ発電所などである.