すべての製品

-

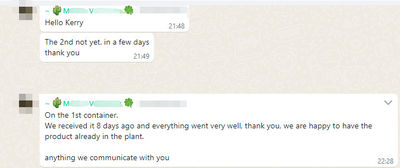

氏「私達は前にそれを8日受け取り、すべては非常によく感謝する私達によってが持って幸せである行った 植物のプロダクト既に。私達があなたと」伝える何でも

氏「私達は前にそれを8日受け取り、すべては非常によく感謝する私達によってが持って幸せである行った 植物のプロダクト既に。私達があなたと」伝える何でも -

氏「こんにちはケリー、私達はパネルのそれ以上のテストをし、結果と幸せ」である。

氏「こんにちはケリー、私達はパネルのそれ以上のテストをし、結果と幸せ」である。 -

ミセスとても満足しています. 良い製品です. 迅速な送料とすべてが非常にうまく行きました.

ミセスとても満足しています. 良い製品です. 迅速な送料とすべてが非常にうまく行きました.

高品質のプレエンジニアリングスチールビルディング構造航空機格納庫材料会社ホットセールモダンプレハブ倉庫、溶接フレーム付き、カスタムメイドソリューション、3Dモデル設計、CE認証

| 起源の場所 | 河北省、中国 |

|---|---|

| ブランド名 | BAODU |

| 証明 | ISO9001,CE |

| モデル番号 | 鉄鋼倉庫 |

| 文書 | 製品説明書 PDF |

| 最小注文数量 | 1000平方メートル |

| 価格 | $45-65square meter |

| パッケージの詳細 | 一般的に鉄骨造の場合、商品が壊れないように鉄骨パッキンを使用します。サンドイッチパネル、カラー鋼板には樹脂パッキンを使用しております。クライアントが特別な梱包を必要とする場合は、要件に従って行います。 |

| 受渡し時間 | 30日間 |

| 支払条件 | L/C、D/A、D/P、T/T、ウェスタンユニオン、マネーグラム |

| 供給の能力 | 100,000 平方メートル/平方メートル/月 |

商品の詳細

| 製品名 | 事前に設計された鋼鉄建物の構造格納庫材料会社ホット販売現代プレハブ倉庫 3D モデル設計 CE 認証 | 加工サービス | 曲げ、溶接、デコイ、切断、打ち抜き |

|---|---|---|---|

| デザイン | SAP2000/AutoCAD/PKPM/3D3S/TEKLA | プロジェクトソリューション能力 | 3Dモデル設計、プロジェクトのための総解決 |

| サイズ | 顧客の要求に応じて | 材料 | Q235B/Q345B 低炭素鋼 |

| パッキング | 標準梱包 | 屋根と壁 | ダンボール/EPS/PU/ロックウール/グラスウール |

| 可搬性 | トラックや船で簡単に輸送可能 | ウィンドウ | アルミ合金スライドウィンドウ |

| アフターサービス | オンライン技術サポート 無料のスペアパーツ | ||

| ハイライト | 溶接フレーム付きプレハブスチール倉庫,カスタム航空機格納庫スチール構造,CE認証済みプレハブ倉庫設計 |

||

製品の説明

高品質のプレエンジニアリング鋼構造物

溶接フレーム、3Dモデル設計、CE認証を備えた、航空機格納庫、倉庫、工業施設などのカスタム設計の鋼構造物。

材料仕様

| プロジェクト | 鉄骨構造物 |

|---|---|

| サイズ | お客様のニーズに合わせて |

| 主要鉄骨構造フレーム | |

| 柱 | Q235B、Q355B 溶接H形鋼 |

| 梁 | Q235B、Q355B 溶接H形鋼 |

| 二次鉄骨構造フレーム | |

| 母屋 | Q235B C型およびZ型鋼 |

| ニーブレース | Q235B C型およびZ型鋼 |

| タイチューブ | Q235B 丸鋼管 |

| ブレース | Q235B 丸鋼 |

| 垂直および水平サポート | Q235B アングル鋼、丸鋼または鋼管 |

| 屋根と壁システム | |

| 屋根クラッディング | 鋼板またはサンドイッチパネル(EPS、PU、グラスウール、ロックウール) |

| 壁クラッディング | 鋼板またはサンドイッチパネル(EPS、PU、グラスウール、ロックウール) |

| ドア | サンドイッチパネル引き戸/金属製ローリングドア |

| 窓 | アルミニウム合金窓/PVCパネル窓 |

技術的パラメータ

お見積りのために以下の情報をご提供ください:

- プロジェクトの進捗状況:土地は購入済みですか?政府の許可はありますか?

- 用途:倉庫、ワークショップ、ショールームなど

- 場所:建物が建設される国

- 現地の気候:風速、積雪荷重(最大風速)

- 設計:設計図を提供するか、当社の設計サービスを依頼してください

- 寸法:長さ × 幅 × 高さ

- クレーンビーム:内部クレーンビームの要件

- 屋根と壁:パネル材料の選択

- 窓とドア:材料、数量、およびタイプの仕様

主要コンポーネント

- コスト削減と輸送に便利な設計

- 高品質の鋼材で作られた主梁と柱

- 強風(140km/h)と震度8の地震に耐える

- 損傷なしで簡単に組み立ておよび分解可能

- さまざまな建設シナリオでの幅広い用途

- 環境に優しくリサイクル可能な材料

製造プロセス

鉄骨構造物は、柱、梁、基礎、屋根トラスなど、鋼で作られた主要な耐荷重部材を特徴としています。屋根と壁システムは、さまざまな用途に合わせて、サンドイッチパネル、鋼板、金網、発泡セメント板などのさまざまな材料を利用しています。

接続方法: 柱は、事前に埋め込まれたアンカーボルトを介して基礎に接続します。梁と柱は、高強度ボルトを使用して接続します。

建設上の利点:

- 特定の目的と環境条件に合わせたカスタム設計

- 50年を超える長寿命

- 経済効率の高い迅速かつ簡単な設置

- 移設可能でリサイクル可能な構造

- 強力な耐震性と耐風性

プロジェクト事例

品質管理

原材料から設置まで、厳格な監督による全工程の品質管理を実施しています。当社の専門的な品質検査チームは、ドイツのGS1000真空分光計や高周波赤外線炭素硫黄分析装置などの高度な機器を使用しています。

認証

会社概要

Baodu International Advanced Construction Material Co., Ltdは、2010年1月に設立され、北京にオフィス、河北省に工場があります。当社は、産業用騒音対策、鉄骨構造物、サンドイッチパネル、プレハブ住宅を専門としています。

年間生産能力には、600万平方メートルの吸音サンドイッチパネル、10万トンの鉄骨構造物、100万平方メートルの床デッキシートが含まれます。当社の製品は、世界30カ国以上で利用されています。

当社の専門設計チームには、5人の上級エンジニア、20人のエンジニア、35人の技術者がおり、10年以上の経験があります。当社は、複数の省エネ特許、建設資格、CE認証、ロシアGOST認証を保持しています。

注目すべきプロジェクトには、中国の60周年記念軍事パレード村と北京大興国際空港があります。また、中国の「一帯一路」構想の下、パキスタンとドバイでも国際プロジェクトを実施しています。

梱包と発送

梱包の詳細:

- 適切な保護を備えた鉄骨構造コンポーネント

- プラスチックフィルムで覆われたサンドイッチパネル

- 木箱に入ったボルトと付属品

- 標準的な海上輸送用梱包

- クレーンとフォークリフトによる専門的な積み込み

よくある質問

1. 品質管理はどのように行っていますか?

当社の製品は、ISO9001、CEの認証を取得しています。

2. 設計サービスを提供できますか?

はい、お客様の要件に合わせて設計できるエンジニアリングチームがあります。さまざまなプロジェクト段階で確認するために、建設図面、構造図面、処理詳細、および設置図面を提供します。

3. サンプルを提供していますか?

はい、サンプルを提供できます。お客様は、運賃をご負担ください。

4. 納期はどのくらいですか?

納期は建物のサイズと数量によって異なり、通常は支払い受領後15〜30日です。大量注文の場合は、部分的な出荷が可能です。

5. 設置サービスを提供していますか?

詳細な建設図面と設置マニュアルを提供しています。必要に応じて、設置を支援するためにエンジニアを派遣できます。

6. 見積もりはどのように入手できますか?

オンラインまたはメールでお問い合わせください。正確な見積もりと図面については、図面または建物の寸法(長さ、幅、軒の高さ)と現地の気象条件をご提供ください。

7. お支払い方法は?

生産前に30%のデポジット、残りの70%は船荷証券のコピーまたは信用状の提示時。

推薦されたプロダクト