-

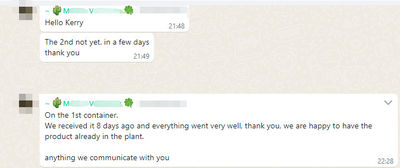

氏「私達は前にそれを8日受け取り、すべては非常によく感謝する私達によってが持って幸せである行った 植物のプロダクト既に。私達があなたと」伝える何でも

氏「私達は前にそれを8日受け取り、すべては非常によく感謝する私達によってが持って幸せである行った 植物のプロダクト既に。私達があなたと」伝える何でも -

氏「こんにちはケリー、私達はパネルのそれ以上のテストをし、結果と幸せ」である。

氏「こんにちはケリー、私達はパネルのそれ以上のテストをし、結果と幸せ」である。 -

ミセスとても満足しています. 良い製品です. 迅速な送料とすべてが非常にうまく行きました.

ミセスとても満足しています. 良い製品です. 迅速な送料とすべてが非常にうまく行きました.

Fast Install Prefabricated Workshops Plants Sandwich Panel Modern Steel Structure Warehouse Hot Selling Factory Wholesale Construction Cheap Steel Building

| 起源の場所 | 河北省、中国 |

|---|---|

| ブランド名 | BAODU |

| 証明 | ISO9001,CE |

| モデル番号 | スチールウェアハウス |

| 文書 | 製品説明書 PDF |

| 最小注文数量 | 300スクエアメーター |

| 価格 | $30-45square meter |

| パッケージの詳細 | 一般に、鋼構造のために、鋼フレームパッキングを使用して、商品を壊さないようにします。サンドイッチパネルとカラースチールシートには、プラスチック製の梱包を使用します。クライアントが要件に応じて特別な梱包 |

| 受渡し時間 | 30日間 |

| 支払条件 | L/C、D/A、D/P、T/T、ウェスタンユニオン、マネーグラム |

| 供給の能力 | 月額100000平方メートル/平方メートル |

試供品およびクーポンのための私に連絡しなさい。

WhatsAPPについて:0086 18588475571

微信: 0086 18588475571

スカイプ: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

x| 製品名 | プレハブ工場工場サンドイッチパネル現代鉄骨構造倉庫 | 加工サービス | 曲げ、溶接、デコイ、切断、打ち抜き |

|---|---|---|---|

| ブレース | 丸いバー/アングルスチール/スチールロッド | デザイン | Sap2000/Autocad/Pkpm/3D3s/Tekla |

| 命を使う | 50年以上 | 腐食防止 | ホットディップの亜鉛メッキ |

| 製品タイプ | スチールウェアハウス | 一生 | 50年以上 |

| 母屋 | CZシェイプスチールチャネル | サイズ | 顧客の要件に応じて |

| 耐久性 | 腐食 に 耐える,気象 に 耐える | メインフレーム | 溶接Hスチールビーム、スチールトラス |

| 輸送可能性 | トラックや船で簡単に輸送可能 | ||

| ハイライト | prefabricated steel warehouse panels,modern steel structure warehouse,cheap prefab steel building |

||

Steel structure buildings are modern construction systems where primary load-bearing components are made of steel, including columns, beams, foundations, and roof trusses. Roof and wall systems utilize various materials such as sandwich panels, steel sheets, wire mesh, and foam cement boards to suit diverse building applications.

Connection Method: Columns connect to foundations via pre-embedded anchor bolts. Beams and columns are joined using high-intensity bolts.

Construction Advantages:

- Custom design for specific purposes and environmental conditions

- Long service life exceeding 50 years

- Quick and easy installation with cost-effectiveness

- Relocatable and recyclable structures

- Strong seismic and wind resistance capabilities

| Structure | Component | Specification |

|---|---|---|

| Main Structure | Frame Column and Beam | Q355B H/I Section & As drawings |

| Welding | Automatic Submerged Arc Welding | |

| Rust Removing | Shot Blasting | |

| Surface Processing | Coating or Galvanized | |

| Secondary Structure | Purlin | C/Z Purlin Size from C120-C320, Z100~Z300 |

| Roof System | Roofing Material | Sandwich Panel-Insulated PU/Glasswool/Rock Wool/EPS 50mm-200mm |

| Wall System | Wall Material | Sandwich Panel-Insulated PU/Glasswool/Rock Wool/EPS 50mm-200mm |

| Additional Features | Ventilator, Doors, Windows, Crane | Customizable options available |

Please provide the following information for your steel structure project:

- Project site location

- Overall dimensions (length × width × eave height in meters)

- Mezzanine requirements and load capacity per square meter

- Wall system preference (single-layer steel sheet or sandwich panel)

- Snow load specifications (if applicable)

- Wind speed/load conditions

- Interior column allowances

- Overhead crane requirements and capacity

- Any other specific requirements

- Cost-effective with convenient transportation and custom design options

- Main beams and columns manufactured from certified steel materials

- Designed to withstand 140km/h winds and 8-grade earthquakes

- Easy assembly and disassembly without structural damage

- Wide application in construction sites, office buildings, dormitories, etc.

- Environmentally friendly construction with recyclable materials

- Logistics & Distribution: High-bay storage systems with narrow aisle compatibility

- Advanced Manufacturing: Vibration-dampened floors for precision equipment

- Food & Pharmaceutical: Hygienic designs with smooth, cleanable surfaces

- Energy Sector: Explosion-resistant designs for hazardous environments

- Small component sections with lightweight construction for easy transport and installation

- Excellent seismic performance with uniform internal steel structure

- Factory mechanized production ensures high precision and fast assembly

Our prefabricated steel buildings are pre-cut, pre-drilled, and ready for quick assembly. Suitable for agricultural buildings, aircraft hangars, commercial centers, warehouses, workshops, schools, and more.

BAODU GROUP implements comprehensive quality management throughout all processes including raw material supply, engineering design, manufacturing, and installation. We maintain a professional quality inspection team with advanced equipment including German GS1000 vacuum spectrometers and high-frequency infrared carbon sulfur analyzers.

We support third-party testing and certification by SGS, TUV, and BV.

Baodu International Advanced Construction Material Co., Ltd was established in 2010 with offices in Beijing and manufacturing facilities in Hebei, China. We specialize in design, manufacturing, and export of industrial noise treatment systems, steel structures, sandwich panels, and prefab houses.

Annual production capacity includes 6 million square meters of acoustic sandwich panels, 100,000 tons of steel structures, and 1 million square meters of floor decking sheets, serving over 30 countries worldwide.

Our professional design team includes 5 senior engineers, 20 engineers, and 35 technicians with over 10 years of experience. We hold multiple environmental protection intellectual property rights and international certifications including CE and GOST.

Packaging Details:

- Steel structure components with protective packaging

- Sandwich panels covered with plastic film

- Bolts and accessories packed in wooden boxes

All components are packed for ocean transport in 40'HQ containers. We maintain strong relationships with shipping companies to ensure smooth transportation.