すべての製品

-

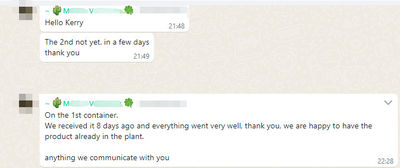

氏「私達は前にそれを8日受け取り、すべては非常によく感謝する私達によってが持って幸せである行った 植物のプロダクト既に。私達があなたと」伝える何でも

氏「私達は前にそれを8日受け取り、すべては非常によく感謝する私達によってが持って幸せである行った 植物のプロダクト既に。私達があなたと」伝える何でも -

氏「こんにちはケリー、私達はパネルのそれ以上のテストをし、結果と幸せ」である。

氏「こんにちはケリー、私達はパネルのそれ以上のテストをし、結果と幸せ」である。 -

ミセスとても満足しています. 良い製品です. 迅速な送料とすべてが非常にうまく行きました.

ミセスとても満足しています. 良い製品です. 迅速な送料とすべてが非常にうまく行きました.

Export-Oriented Steel Structure Building Prefab Workshop & Warehouse with Steel Components Customizable Layout Energy-Efficient Anti-Corrosive Anti-Seismic Ideal for Heavy-Duty Manufacturing Storage

| 起源の場所 | 河北省、中国 |

|---|---|

| ブランド名 | BAODU |

| 証明 | ISO9001,CE |

| モデル番号 | スチールウェアハウス |

| 文書 | 製品説明書 PDF |

| 最小注文数量 | Discussible |

| 価格 | Reasonable |

| パッケージの詳細 | 一般に、鋼構造のために、鋼フレームパッキングを使用して、商品を壊さないようにします。サンドイッチパネルとカラースチールシートには、プラスチック製の梱包を使用します。クライアントが要件に応じて特別な梱包 |

| 受渡し時間 | 15-21Days |

| 支払条件 | L/C、D/A、D/P、T/T、ウェスタンユニオン、マネーグラム |

| 供給の能力 | 月額10000平方メートル/平方メートル |

試供品およびクーポンのための私に連絡しなさい。

WhatsAPPについて:0086 18588475571

微信: 0086 18588475571

スカイプ: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

x商品の詳細

| 製品名 | 輸出志向の鉄骨構造の建物 鉄鋼コンポーネントを備えたプレハブ ワークショップと倉庫 カスタマイズ可能なレイアウト エネルギー効率の高い 防食性 耐震性 頑丈な製造保管に最適 | キーワード | 鉄骨構造の建物の倉庫 |

|---|---|---|---|

| 構造 | 溶接された鋼構造フレーム | 屋根の被覆 | EPS/岩毛/ガラス繊維の羊毛/PUサンドイッチパネルまたは鋼板 |

| 加工サービス | 曲げ、溶接、デコイ、切断、打ち抜き | 命を使う | 50年以上 |

| 窓およびドア | PVC/アルミニウム | メインフレーム | Q355 Q235 |

| 図面デザイン | AutoCAD /PKPM /3D3S/TEKLA | インストール | 迅速で簡単なアセンブリ |

| 価格条件 | FOB CIF CFR EXW | ウィンドウ | アルミ合金の窓、プラスチック鋼鉄 |

| 屋根の被覆 | 波形鋼板/サンドイッチパネル | 輸送と積み込み | 容器の輸送 |

| インストールガイド | インストール図面とビデオ | ||

| ハイライト | prefab steel warehouse with anti-corrosive coating,customizable steel structure building for heavy-duty storage,energy-efficient prefab workshop with seismic resistance |

||

製品の説明

Export-Oriented Prefab Steel Structure Building

Customizable prefabricated steel structure workshop and warehouse with steel components. Designed for heavy-duty manufacturing and storage applications with energy-efficient, anti-corrosive, and anti-seismic properties.

| Type | Prefabricated Steel Structure Building |

|---|---|

| Brand Name | Baodu |

| Place of Origin | Shenyang, China |

| Main Steel Frame | H Section Steel Beam and Columns, Welded H steel, material grade: Q355B (equivalent to S355JR, ASTM A572 Gr. 50) |

| Secondary Frame | Hot Dip Galvanized C Purlin, Steel Bracing, Tie Bar, Knee Brace, material grade: Q235B (equivalent to S235JR, ASTM A36) |

| Roof Panel | EPS Sandwich Panel, Glass Fiber Sandwich Panel, Rock Wool Sandwich Panel, and PU Sandwich Panel or Steel Sheet |

| Wall Panel | EPS Sandwich Panel, Glass Fiber Sandwich Panel, Rock Wool Sandwich Panel, and PU Sandwich Panel or Steel Sheet |

| Roof Gutter | Color Steel Sheet |

| Certification | ISO9001:2000, CE, SGS, AISC, CWB, etc. |

Technical Parameters

We provide comprehensive design and detailing services using modern software including AutoCAD, PKMK, 3D3S, SAP 2000, TSSD, TEKLA, and 3DS MAX.

Our structural steel solutions provide strong, durable, and flexible frameworks for construction projects. We have extensive project cooperation experience for your reference.

Custom Project Requirements

To receive a customized quotation, please provide the following information:

- Location (country, area)

- Size: Length × width × height

- Wind load (maximum wind speed)

- Snow load (maximum snow height)

- Anti-earthquake level

- Brickwall requirement (height if needed)

- Thermal insulation type preference

- Door quantity and dimensions

- Window quantity and dimensions

- Crane requirements (quantity, lifting capacity, height)

Applications

Steel structure buildings are versatile and suitable for various industrial and commercial uses:

- Manufacturing Facilities: Automotive plants, machinery workshops, food processing plants

- Warehouses & Logistics Centers: Distribution hubs, cold storage, bulk storage facilities

- Aircraft Hangars: Requiring very large, clear-span areas

- Power Stations & Substations

- Agricultural Buildings: Large barns, storage silos, and processing facilities

- Retail Outlets & Superstores (Big-Box Stores)

Construction Process

- Design & Engineering: Creating detailed architectural and structural drawings with load calculations

- Fabrication: Cutting, welding, and drilling steel components in controlled factory environment

- Site Preparation & Foundation: Excavation and pouring of concrete foundations with anchor bolts

- Erection: Assembling primary steel frame followed by secondary elements

- Enclosure: Installing roof and wall cladding systems with insulation

- Finishing: Adding doors, windows, ventilation systems, skylights, and interior finishes

Packing and Shipping

Our prefab steel warehouse components are carefully packed to ensure safe delivery. Each component is securely wrapped and palletized to prevent damage during transit. Detailed assembly instructions are included for easy setup.

We offer worldwide shipping with costs varying by destination and order quantity. Contact our customer service team for shipping quotes and delivery timelines.

Company Profile

Baodu International Advanced Construction Material Co., Ltd was established in January 2010 with offices in Beijing and factory in Hebei, China. We are designers, manufacturers, suppliers, and exporters of industrial noise treatment solutions, steel structures, sandwich panels, and prefab houses.

Our annual production capacity includes 6 million square meters of acoustic sandwich panels, 100,000 tons of steel structures, and 1 million square meters of floor decking sheet. Our products are sold in more than 30 countries worldwide.

We maintain a professional design team with over 10 years of experience, including 5 senior engineers, 20 engineers, and 35 technicians. Baodu holds several energy-saving and environmental protection intellectual property rights, construction and environmental protection design qualifications, CE certification, and Russian GOST certification.

Notable projects include the military parade village for China's 60th anniversary and Beijing Daxing International Airport. Under China's "One Belt, One Road" initiative, we've undertaken overseas projects including Thar, Pakistan coal-fired power plant and Hasyan Dubai power plant.

Frequently Asked Questions

Q1: What parameters do you need to customize a steel structure building?

Please prepare the following information: Project site location, overall dimensions (Length × Width × Eave Height in meters), mezzanine requirements and load capacity, snow load measurements, wind speed or load specifications, and overhead crane requirements with capacity.

Q2: Can you provide the design service?

Yes, we provide comprehensive design services using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (Xsteel). We design complex industrial buildings including office buildings, supermarkets, auto dealer shops, shopping malls, and 5-star hotels.

Q3: How do you have the quality control procedure? What quality assurance can you provide?

We implement quality checks throughout all fabrication stages including raw materials, in-process materials, validated/tested materials, and finished goods. SGS, BV and other testing services are available.

Q4: Can you accept container loading inspection?

You are welcome to send an inspector at any time during production, including container loading.

Q5: Is your price competitive compared with other companies?

Our business objectives are to provide the best price for the same quality and the best quality for the same price. We work to reduce your costs while guaranteeing the best product for your investment.

Q6: Can you send engineers or whole team to install my project?

Yes, we provide detailed installation drawings and videos for free. We can also provide installation, supervision, and training services, and send professional technical teams to supervise overseas installation.

Q7: What is the delivery time?

Delivery time depends on order quantities. Typically, delivery to the nearest seaport in China is 30 days after receiving deposit.

Q8: How can you get a quotation for your projects?

Contact us by email, phone, WhatsApp, Skype, etc. 24/7 and receive a reply within 8 hours.

Q9: How to ensure the product you supply is what we want exactly?

Before ordering, our sales and engineering teams provide suitable solutions based on your requirements. We offer proposal drawings, 3D drawings, material photos, and finished project photos to help you understand our solutions.

推薦されたプロダクト