すべての製品

-

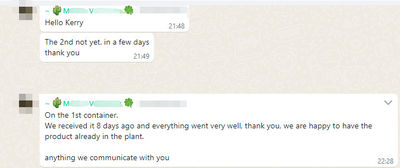

氏「私達は前にそれを8日受け取り、すべては非常によく感謝する私達によってが持って幸せである行った 植物のプロダクト既に。私達があなたと」伝える何でも

氏「私達は前にそれを8日受け取り、すべては非常によく感謝する私達によってが持って幸せである行った 植物のプロダクト既に。私達があなたと」伝える何でも -

氏「こんにちはケリー、私達はパネルのそれ以上のテストをし、結果と幸せ」である。

氏「こんにちはケリー、私達はパネルのそれ以上のテストをし、結果と幸せ」である。 -

ミセスとても満足しています. 良い製品です. 迅速な送料とすべてが非常にうまく行きました.

ミセスとても満足しています. 良い製品です. 迅速な送料とすべてが非常にうまく行きました.

Fast Easy Assemble Fully Customization Design Prefab Factory Storage Steel Structure Workshop Building

| 起源の場所 | 中国、ヘベイ |

|---|---|

| ブランド名 | BAODU |

| 証明 | ISO9001,CE |

| モデル番号 | スチールウェアハウス |

| 文書 | 製品説明書 PDF |

| 最小注文数量 | Discussible |

| 価格 | Reasonable |

| パッケージの詳細 | 一般に、鋼構造のために、鋼フレームパッキングを使用して、商品を壊さないようにします。サンドイッチパネルとカラースチールシートには、プラスチック製の梱包を使用します。クライアントが要件に応じて特別な梱包 |

| 受渡し時間 | 15-21Days |

| 支払条件 | L/C、D/A、D/P、T/T、ウェスタンユニオン、マネーグラム |

| 供給の能力 | 月額10000平方メートル/平方メートル |

試供品およびクーポンのための私に連絡しなさい。

WhatsAPPについて:0086 18588475571

微信: 0086 18588475571

スカイプ: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

x商品の詳細

| 製品名 | 速く簡単に組み立てる完全にカスタマイズ設計プレハブ工場保管鉄骨構造ワークショップビル | キーワード | 鉄骨構造の建物の倉庫 |

|---|---|---|---|

| アフターサービス | オンライン技術サポート | 材料 | Q235/Q345スチール |

| 構造 | 鋼構造フレームが溶接されています | 屋根の被覆 | EPS/岩毛/ガラス繊維の羊毛/PUサンドイッチパネルまたは鋼板 |

| 加工サービス | 曲げ、溶接、デカイル、切断、パンチ | 人生を使う | 50年以上 |

| ドア | ローリングドアまたはサンドイッチパネルドア | 窓およびドア | PVC/アルミニウム |

| メインフレーム | Q355 Q235 | 図面デザイン | AutoCAD /PKPM /3D3S /TEKLA |

| ハイライト | prefab steel warehouse building,customizable steel workshop structure,easy assemble storage building |

||

製品の説明

Fast Easy Assemble Fully Customization Design Prefab Factory Storage Steel Structure Workshop Building

HI, Dear friend, Please Attention

Steel structure building is one kind of product which can be designed as per every person's different needs. If you find that the example pictures are not the same as what you want, or even very different, do not worry. No matter what kind of building you need - prefabricated houses, warehouses (bigger, smaller or multi-storey) - just tell us the data or drawing of the building you require. We will make the exact design, quotation and rendering for you as soon as possible (our group has more than 20 years experience in steel structures).

Key Features & Structural System

Primary Framework:

- Columns: Hot-rolled H-section steel or welded box sections that provide vertical support.

- Beams: Typically H-sections or I-beams that span between columns, supporting the roof and floors.

- Roof Trusses/Purlins: Trusses or lighter purlins (C/Z-sections) that support the roof covering.

- Wall Girts: Horizontal members attached to columns that support the wall cladding.

Secondary Elements:

- Roof and Wall Cladding: Corrugated steel sheets, sandwich panels (for insulation), or other composite materials.

- Bracing Systems: Diagonal steel rods or cables that provide stability against lateral forces like wind and earthquakes.

Connections:

High-strength bolts and welding are used to connect all components, ensuring a robust and integrated structure.

Technical Parameters

If you are interested in our steel structure, please provide the following information:

- Location (where will be built?) _____country, area

- Size: Length*width*height _____mm*_____mm*_____mm

- Wind load (max. Wind speed) _____kn/m2, _____km/h, _____m/s

- Snow load (max. Snow height)____kn/m2, _____mm

- Anti-earthquake _____level

- Brickwall needed or not If yes, 1.2m high or 1.5m high

- Thermal insulation If yes, EPS, fiberglass wool, rockwool, PU sandwich panels will be suggested; If not, the metal steel sheets will be ok. The cost of the latter will be much lower than that of the former.

- Door quantity & size _____units, _____(width)mm*_____(height)mm

- Window quantity & size _____units, _____(width)mm*_____(height)mm

- Crane needed or not If yes, _____units, max. Lifting weight____tons; Max. Lifting height ___m.

Applications

Wide Range of Applications

Steel structure buildings are versatile and suitable for various industrial and commercial uses:

- Manufacturing Facilities: Automotive plants, machinery workshops, food processing plants.

- Warehouses & Logistics Centers: Distribution hubs, cold storage, bulk storage facilities.

- Aircraft Hangars: Requiring very large, clear-span areas.

- Power Stations & Substations

- Agricultural Buildings: Large barns, storage silos, and processing facilities.

- Retail Outlets & Superstores (Big-Box Stores)

The Construction Process

- Design & Engineering: Creating detailed architectural and structural drawings, including calculations for loads and connections.

- Fabrication: Cutting, welding, and drilling steel components in a controlled factory environment based on the design.

- Site Preparation & Foundation: Excavation and pouring of concrete foundations, often with embedded anchor bolts.

- Erection: Assembling the primary steel frame (columns, beams), followed by the secondary elements (purlins, girts).

- Enclosure: Installing the roof and wall cladding systems, along with insulation.

- Finishing: Adding doors, windows, ventilation systems, skylights, and interior finishes.

Packing and Shipping

Our Prefab Steel Warehouse is carefully packed to ensure safe delivery. Each component is securely wrapped and palletized to prevent any damage during transit. Detailed assembly instructions are included for easy setup.

Shipping:

We offer worldwide shipping for our Prefab Steel Warehouse. Shipping costs may vary depending on the destination and order quantity. Please contact our customer service team for a shipping quote and delivery timeline.

Company Profile

Baodu International Advanced Construction Material Co., Ltd was established in January 2010 with the office in Beijing and factory in Hebei, China. Baodu is a designer, manufacturer, supplier and exporter of industrial noise comprehensive treatment, steel structure, sandwich panel and prefab house.

Baodu has an annual output of 6 million square meters of acoustic sandwich panels, 100000 tons of steel structures and 1 million square meters of floor decking sheet. The products are sold in more than 30 countries and regions around the world.

Baodu has a professional design team with more than 10 years' experience, including 5 senior engineers, 20 engineers, and 35 technicians. Baodu has several energy saving and environment protection intellectual property rights, construction and environment protection design qualification, CE certification and Russian GOST certification etc.

Baodu participated in the military parade village project for the 60th anniversary of China and project of Beijing Daxing International Airport. Under the guidance of China's "one belt, one road" strategy, Baodu has also undertaken overseas projects such as the project of Thar,Pakistan coal fired power plant, Hasyan Dubai power plant and so on. Finally, welcome your coming to Baodu for a visit and cooperation!

FAQ

Q: Are you a manufacturing factory or a foreign trade company?

A: We are an integrated enterprise of industry and trade, integrating steel structure building design optimization, fabrication and installation, and service. We sincerely invite you to visit our factory and we will arrange our professional team to customize the steel structure solution for you.

Q: Does the steel used by your company meet international quality standards? How to ensure the durability of the material?

A: We strictly use high-quality steel materials that meet the standards set by our customers or are higher than the national standards of GB (e.g. Q355B high-strength steel), and all the materials are accompanied by manufacturers' certificates of conformity and third-party test reports. At the request of customers, we can ensure that the steel structure meets the design environment to achieve the service life and standard requirements through hot-dip galvanizing, fireproof coating and other processes.

Q: Where can your steel structure be used?

A: With modular design and international standard certification, our steel structure systems can be widely used in the following fields, covering the mainstream engineering scenarios in the world: intelligent factories, manufacturing workshops, logistics and warehousing centers, shopping malls, high-rise office buildings, stadiums, exhibition centers, photovoltaic power stations, wind towers, airport terminals, high-speed rail stations, modular buildings, greenhouses, poultry houses, light steel villas, bridges, and other buildings.

Q: What are the core advantages of steel structure building compared with concrete structure?

A:

- High strength-to-weight ratio: 40% weight reduction, lower foundation cost

- Short construction cycle: no maintenance period, construction as usual in rainy seasons

- Environmentally friendly and recyclable: steel recycling rate of 90%, dust pollution reduction of 75%

Q: Is the maintenance cost of steel structure plant high? What routine maintenance is needed?

A: The annual maintenance cost is only 0.8%-1.2% of the construction cost, mainly including:

- Checking the tightness of bolts and rustproof layer every 2 years

- Fire retardant coating every 5 years

- Checking the drainage system after a storm

推薦されたプロダクト