-

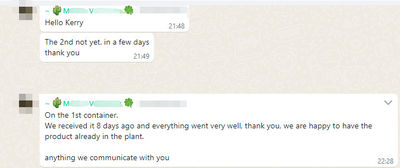

氏「私達は前にそれを8日受け取り、すべては非常によく感謝する私達によってが持って幸せである行った 植物のプロダクト既に。私達があなたと」伝える何でも

氏「私達は前にそれを8日受け取り、すべては非常によく感謝する私達によってが持って幸せである行った 植物のプロダクト既に。私達があなたと」伝える何でも -

氏「こんにちはケリー、私達はパネルのそれ以上のテストをし、結果と幸せ」である。

氏「こんにちはケリー、私達はパネルのそれ以上のテストをし、結果と幸せ」である。 -

ミセスとても満足しています. 良い製品です. 迅速な送料とすべてが非常にうまく行きました.

ミセスとても満足しています. 良い製品です. 迅速な送料とすべてが非常にうまく行きました.

Steel Grade Sheet Cladding Light Steel Warehouse Commercial Prefabricated Building Steel Structures Workshop

| 起源の場所 | 中国、ヘベイ |

|---|---|

| ブランド名 | BAODU |

| 証明 | ISO9001,CE |

| モデル番号 | スチールウェアハウス |

| 文書 | 製品説明書 PDF |

| 最小注文数量 | 800平方メートル |

| 価格 | $24-28square meter |

| パッケージの詳細 | 一般に、鋼構造のために、鋼フレームパッキングを使用して、商品を壊さないようにします。サンドイッチパネルとカラースチールシートには、プラスチック製の梱包を使用します。クライアントが要件に応じて特別な梱包 |

| 受渡し時間 | 30日間 |

| 支払条件 | L/C、D/A、D/P、T/T、ウェスタンユニオン、マネーグラム |

| 供給の能力 | 月額100000平方メートル/平方メートル |

試供品およびクーポンのための私に連絡しなさい。

WhatsAPPについて:0086 18588475571

微信: 0086 18588475571

スカイプ: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

x| 製品名 | Q355 鋼グレード シート クラッディング 軽鋼倉庫商業プレハブ建築鉄骨構造ワークショップ | 加工サービス | 曲げ、溶接、デカイル、切断、パンチ |

|---|---|---|---|

| ブレース | 丸いバー/アングルスチール/スチールロッド | デザイン | Sap2000/Autocad/Pkpm/3D3s/Tekla |

| 人生を使う | 50年以上 | 製品タイプ | スチールウェアハウス |

| 表面処理 | 絵画または亜鉛メッキ | 屋根と壁 | サンドイッチパンネル;鋼板 |

| 材料 | Q235/Q235B/Q355/Q355B | 母屋 | CZシェイプスチールチャネル |

| ハイライト | steel grade sheet cladding,prefabricated steel warehouse building,light steel workshop structures |

||

| Structure | Material | Details |

|---|---|---|

| Main Structure | Frame Columns and Beams | Q235B/Q355B |

| End Wall Column | Q235B/Q355B | |

| H-beam welding(columns and beams) | Automatic Submerged Arc Welding | |

| Rust Removal | Shot Blasting | |

| Surface Processing | Alkyd Paint/Epoxy Zinc Rich/Galvanized | |

| High-Strength Bolt | Grade 10.9/8.8 | |

| Secondary Structure | Flange Brace | Angle Steel |

| Horizontal Support | Angle/Round Steel | |

| Vertical Support | Angle/Round Steel | |

| Tie Rod | Angle/Round Steel | |

| Tie Bars | Round Steel/Casing/Shaped Steel | |

| Enclosure system | Roofing system | 360°Locking Seam System / Locking Screw System / Composite Panel Roofing / Rockwool Maintenance System |

| Daylighting Band: FRP Plate | ||

| Gutter (inside/outside): Stainless Steel/Colored Steel Plate | ||

| Wall System | Locking Screw System / Composite Panel Wall / Rockwool Maintenance System |

- Project site location

- Overall dimension (length*width*eave height in meters)

- Mezzanine or not? How many kgs of load per square meter on mezzanine?

- Single-layer steel sheet wall or sandwich panel wall

- Snow load if applicable

- Wind speed/load

- Interior column allowed or not

- Overhead crane needed or not, capacity?

- Any other particular requirements?

The columns are connected with the foundation by pre-embedding anchor bolt. The beams and columns, beams and beams are connected with high intensity bolts.

- Could be designed according to different purpose and environment condition

- Long life span, could be more than 50 years

- Quick and easy install work and the more economic friendly

- Could be moved and recycle

- Strong seismic and wind resistance

- Logistics & Distribution: High-bay storage systems with narrow aisle compatibility

- Advanced Manufacturing: Vibration-dampened floors for precision equipment

- Food & Pharmaceutical: Hygienic designs with smooth, cleanable surfaces

- Energy Sector: Explosion-resistant designs for hazardous environments

- The components of the steel structure have small section, light weight, easy to transport and installation, suitable for large span, high height, heavy bearing structure.

- Suitable for withstand impact and dynamic load, with good seismic performance. The internal structure of steel is uniform with high reliability.

- Factory mechanized production of steel structure components finished products of high precision, high production efficiency, site assembly speed, short construction period.

Our prefabricated steel structure buildings are pre-cut, pre-drilled, and ready for quick and efficient assembly. Steel buildings work for virtually any building application: Agricultural/ Barns/ Aircraft Hangars/ Welding Shops/Commercial center/Garages/Storage/ Suburban Buildings/ Warehouses/ Workshops/school/wedding hall/dormitory etc.

Excellent product quality is our eternal pursuit, and it is also the fundamental reason for us to base ourselves on the global market. BAODU GROUP implements whole-process quality management and strictly supervises every process such as raw material supply, engineering design, steel component manufacturing, installation and construction.

We have established a professional team of quality inspection engineers, introduced internationally leading quality inspection equipment such as German GS1000 vacuum spectrometer and high-frequency infrared carbon sulfur analyzer, established a high-quality product inspection room, and won many awards from China's advanced quality management unit.

In addition, we support testing and certification by SGS, TUV, BV.

Baodu International Advanced Construction Material Co., Ltd was established in January 2010 with the office in Beijing and factory in Hebei, China. Baodu is a designer, manufacturer, supplier and exporter of industrial noise comprehensive treatment, steel structure, sandwich panel and prefab house.

Baodu has an annual output of 6 million square meters of acoustic sandwich panels, 100000 tons of steel structures and 1 million square meters of floor decking sheet. The products are sold in more than 30 countries and regions around the world.

Baodu has a professional design team with more than 10 years' experience, including 5 senior engineers, 20 engineers, and 35 technicians. Baodu has several energy saving and environment protection intellectual property rights, construction and environment protection design qualification, CE certification and Russian GOST certification etc.

Baodu participated in the military parade village project for the 60th anniversary of China and project of Beijing Daxing International Airport. Under the guidance of China's "one belt, one road" strategy, Baodu has also undertaken overseas projects such as the project of Thar,Pakistan coal fired power plant, Hasyan Dubai power plant and so on. Finally, welcome your coming to Baodu for a visit and cooperation!

- Steel structure components will be in packaging with proper protection.

- Sandwich panels will be covered with plastic film.

- Bolts and other accessories will be loaded into wooden Boxes

All the structure components, panels, bolts and sorts of accessories will be well packed with standard package suitable for ocean transport and loaded into 40'HQ.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged.

Good relationship with many vessel companies to make sure the transportation smooth.

A: Our main products have steel structure,warehouse,workshop,prefab house,container house, steel poultry shed,steel car garage,steel aircraft hangar,light steel villa,sandwich panel and other construction materials.

A: When we receive inquiry from client, client please fills purchasing intention sheet, providing us with information of house dimensions, draft drawing, layout and materials for prefabricated house. We will design the drawings and offer competitive quotation with the above information.

A: Our prefabricated house materials mainly include light steel structure, sandwich panel, roof tile, door, window, covers, screws and other accessories.

A: Plan drawing, elevation drawing, sectional drawing, foundation drawing, installation drawing.

A: Off-white, ivory white, blue, green, red and according to buyer's requirement.