すべての製品

-

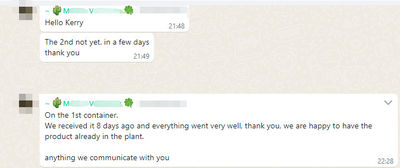

氏「私達は前にそれを8日受け取り、すべては非常によく感謝する私達によってが持って幸せである行った 植物のプロダクト既に。私達があなたと」伝える何でも

氏「私達は前にそれを8日受け取り、すべては非常によく感謝する私達によってが持って幸せである行った 植物のプロダクト既に。私達があなたと」伝える何でも -

氏「こんにちはケリー、私達はパネルのそれ以上のテストをし、結果と幸せ」である。

氏「こんにちはケリー、私達はパネルのそれ以上のテストをし、結果と幸せ」である。 -

ミセスとても満足しています. 良い製品です. 迅速な送料とすべてが非常にうまく行きました.

ミセスとても満足しています. 良い製品です. 迅速な送料とすべてが非常にうまく行きました.

Modern Prefabricated Steel Frame Structure Workshop Assembled Warehouse Construction Steel Building Metal Structure

| 起源の場所 | 中国、ヘベイ |

|---|---|

| ブランド名 | BAODU |

| 証明 | ISO9001,CE |

| モデル番号 | スチールウェアハウス |

| 文書 | 製品説明書 PDF |

| 最小注文数量 | 800平方メートル |

| 価格 | $22-28square meter |

| パッケージの詳細 | 一般に、鋼構造のために、鋼フレームパッキングを使用して、商品を壊さないようにします。サンドイッチパネルとカラースチールシートには、プラスチック製の梱包を使用します。クライアントが要件に応じて特別な梱包 |

| 受渡し時間 | 30日 |

| 支払条件 | L/C、D/A、D/P、T/T、ウェスタンユニオン、マネーグラム |

| 供給の能力 | 月額100000平方メートル/平方メートル |

試供品およびクーポンのための私に連絡しなさい。

WhatsAPPについて:0086 18588475571

微信: 0086 18588475571

スカイプ: sales10@aixton.com

心配があれば、私達は24時間のオンライン・ヘルプを提供する。

x商品の詳細

| 製品名 | 現代のプレハブ鉄骨フレーム構造ワークショップ組み立てられた倉庫建設鉄骨建物の金属構造 | 加工サービス | 曲げ、溶接、デカイル、切断、パンチ |

|---|---|---|---|

| ブレース | 丸いバー/アングルスチール/スチールロッド | デザイン | SAP2000 /AutoCAD /PKPM /3D3S /TEKLA |

| 人生を使う | 50年以上 | 腐食保護 | ホットディップの亜鉛メッキ |

| 製品タイプ | スチールウェアハウス | 一生 | 50年以上 |

| プロジェクトソリューション能力 | 3Dモデル設計 | 屋根と壁のパネル | サンドイッチパネルまたはカラー塗装鋼板 |

| パッキング | 標準梱包 | 描画デザイン | AutOCAD/TEKLA |

| ハイライト | prefabricated steel warehouse building,assembled metal workshop structure,steel frame warehouse construction |

||

製品の説明

Modern Prefabricated Steel Frame Structure Workshop

Our prefabricated steel structure buildings offer efficient, reliable solutions for warehouse construction and industrial applications with advanced engineering and quality materials.

Material Specifications

| Project | Steel Structure Building |

|---|---|

| Size | 27.5x10.5x5.0m |

| Main Steel Structure Frame | |

| Column | Q235B, Q355B Welded or Hot-Roll H Section Steel |

| Beam | Q235B, Q355B Welded or Hot-Roll H Section Steel |

| Secondary Steel Structure Frame | |

| Purlin | Q235B C and Z Type Steel |

| Knee Brace | Q235B Angle Steel |

| Tie Tube | Q235B Circular Steel Pipe |

| Brace | Q235B Round Bar or Angle Steel |

| Vertical and Horizontal Support | Q235B Angle Steel, Round Bar or Steel Pipe |

As a leader in the industry, our steel structure division integrates advanced manufacturing capabilities, technological innovation and strict quality management to provide customers with safe, reliable and cost-effective all-round solutions.

Advanced Structural Properties

- Load Optimization: Computer-optimized designs that efficiently distribute live loads (up to 250 kg/m²), wind loads (up to 200 km/h), and seismic forces

- Dynamic Load Capacity: Specialized designs for crane systems (5-50 ton capacity) with reinforced support structures

- Thermal Efficiency: U-values as low as 0.25 W/m²K through advanced composite insulation systems

Material Science Leadership

We utilize high-strength low-alloy (HSLA) steels with yield strengths ranging from 345 MPa to 460 MPa. Our proprietary corrosion protection system combines:

- Multi-stage surface preparation (SA 2.5 standard)

- Hot-dip galvanizing (minimum 85μm zinc thickness)

- Advanced polymer coatings (PVDF/HDP finishes)

Custom Engineering Solutions

Design Flexibility:

- Clear spans from 15m to 150m without internal supports

- Eave heights from 6m to 40m for multi-level operations

- Custom bay spacing optimized for your operational workflow

Specialized Configurations:

- Multi-Span Complexes: Integrated designs for large-scale manufacturing campuses

- Hybrid Structures: Steel-concrete composite systems for heavy industrial applications

- Temperature-Controlled: Insulated panel systems with air-tight seals for sensitive environments

Technical Parameters

Could you tell me your requirement for your steel structure project?

Basic design requirements and design Load:

- Project site location

- Overall dimension (length*width*eave height in meters)

- Mezzanine or not? How many kgs of load per square meter on mezzanine?

- Single-layer steel sheet wall or sandwich panel wall

- Snow load if applicable

- Wind speed/load

- Interior column allowed or not

- Overhead crane needed or not, capacity?

- Any other particular requirements?

Components

Steel Building Process

Phase 1: Digital Prototyping

- 3D modeling and virtual reality walkthroughs

- Finite element analysis for stress optimization

- Energy modeling and lifecycle cost analysis

Phase 2: Precision Manufacturing

- CNC machining with ±1mm tolerance

- Automated welding (AWS D1.1 standards)

- Quality verification through ultrasonic testing

Phase 3: Global Logistics Management

- Expert cargo optimization for container and break-bulk shipments

- Comprehensive insurance coverage

- Real-time shipment tracking

Phase 4: Commissioning Support

- Detailed erection sequencing plans

- On-site technical supervision available

- Operations and maintenance training

Project Cases

Industry-Specific Solutions

- Logistics & Distribution: High-bay storage systems with narrow aisle compatibility

- Advanced Manufacturing: Vibration-dampened floors for precision equipment

- Food & Pharmaceutical: Hygienic designs with smooth, cleanable surfaces

- Energy Sector: Explosion-resistant designs for hazardous environments

Advantages of Steel Structure Buildings

| The components of the steel structure have small section, light weight, easy to transport and installation, suitable for large span, high height, heavy bearing structure. |

| Suitable for withstand impact and dynamic load, with good seismic performance. The internal structure of steel is uniform with high reliability. |

| Factory mechanized production of steel structure components finished products of high precision, high production efficiency, site assembly speed, short construction period. |

Our prefabricated steel structure buildings are pre-cut, pre-drilled, and ready for quick and efficient assembly. Steel buildings work for virtually any building application: Agricultural/ Barns/ Aircraft Hangars/ Welding Shops/Commercial center/Garages/Storage/ Suburban Buildings/ Warehouses/ Workshops/school/wedding hall/dormitory etc.

Strict Quality Inspection Standards

Excellent product quality is our eternal pursuit, and it is also the fundamental reason for us to base ourselves on the global market. BAODU GROUP implements whole-process quality management and strictly supervises every process such as raw material supply, engineering design, steel component manufacturing, installation and construction.

We have established a professional team of quality inspection engineers, introduced internationally leading quality inspection equipment such as German GS1000 vacuum spectrometer and high-frequency infrared carbon sulfur analyzer, established a high-quality product inspection room, and won many awards from China's advanced quality management unit.

In addition, we support testing and certification by SGS, TUV, BV.

Our Capacity and Certification

Steel Structure Division

Equipped with four advanced production lines and state-of-the-art processing equipment, the division boasts an annual production capacity of over 35,000 tons of steel structures. Its products are widely utilized across a diverse range of applications, including:

- Industrial workshops and storage facilities

- Bridges and super high-rise buildings

- Modular prefabricated buildings

- New energy infrastructure

- Heavy machinery frames

Seamless Steel Pipe Division

Operating four modern hot-rolling production lines, this division achieves an annual output of 200,000 tons of seamless steel pipes. Key product offerings comprise:

- Corrosion-resistant and pressure-resistant oil well pipes

- High-pressure boiler pipes

- Hydraulic prop pipes

- High-precision mechanical pipes

- Structural pipes

These pipes, with an outer diameter range of 38 mm to 219 mm and wall thicknesses from 4 mm to 22 mm, serve critical roles in sectors such as petroleum, chemical engineering, coal mining, machinery, hydraulic supports, and automotive manufacturing.

Competitive Advantages

By integrating German precision technology with China's industrial scale advantages, the group delivers high cost-effectiveness without compromising on quality. Its end-to-end vertically integrated supply chain--spanning from raw material procurement to global logistics--enables consistent product quality, rapid order response, and round-the-clock technical support.

Support and Services

Why Partner With Us?

Proven Track Record:

- 25+ years of specialized experience

- 500+ successful international projects

- 98% on-time delivery record

- 24/7 technical support availability

Value-Added Services:

- Financing Solutions: Flexible payment terms and project financing

- Warranty Package: Comprehensive 25-year structural warranty

- After-Sales Support: Spare parts program and maintenance contracts

Company Profile

Baodu International Advanced Construction Material Co., Ltd was established in January 2010 with the office in Beijing and factory in Hebei, China. Baodu is a designer, manufacturer, supplier and exporter of industrial noise comprehensive treatment, steel structure, sandwich panel and prefab house.

Baodu has an annual output of 6 million square meters of acoustic sandwich panels, 100000 tons of steel structures and 1 million square meters of floor decking sheet. The products are sold in more than 30 countries and regions around the world.

Baodu has a professional design team with more than 10 years' experience, including 5 senior engineers, 20 engineers, and 35 technicians. Baodu has several energy saving and environment protection intellectual property rights, construction and environment protection design qualification, CE certification and Russian GOST certification etc.

Baodu participated in the military parade village project for the 60th anniversary of China and project of Beijing Daxing International Airport. Under the guidance of China's "one belt, one road" strategy, Baodu has also undertaken overseas projects such as the project of Thar,Pakistan coal fired power plant, Hasyan Dubai power plant and so on. Finally, welcome your coming to Baodu for a visit and cooperation!

Packing and Shipping

Packaging Details:

- Steel structure components will be in packaging with proper protection.

- Sandwich panels will be covered with plastic film.

- Bolts and other accessories will be loaded into wooden Boxes

All the structure components, panels, bolts and sorts of accessories will be well packed with standard package suitable for ocean transport and loaded into 40'HQ.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent the goods to be damaged.

Good relationship with many vessel companies to make sure the transportation smooth.

FAQ

Q1: You are manufacture factory or trading company?

A: We are manufacture factory. And you are welcomed to visit us at any time for inspection. The quality control flow and sales team will show you our professionalism. Also, you will get best and most competitive price after visiting us.

Q2: What the quality assurance you provided and how do you control quality?

A: Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials,validated or tested materials, finished goods, etc. SGS, BV and other testing are available for us. We could deal with you by Trade Assurance via Alibaba.

Q3: Is your price competitive compared with other companies?

A: Our business objectives are to give the best price with same quality and best quality with the same price. We will do everything we can to reduce your cost and guarantee you get the best product that you paid for.

Q4: Can you send engineers or whole team to install my project?

A: Yes, we will send you the detailed installation drawing and video for free, we can provide the service of installation, supervision, and training by extra. We can send our professional technical team to supervise installation on site overseas.

Q5: Do you accept container loading inspection?

A: You are welcomed to send an inspector, not only for the container loading, but any time during the production time.

Q6: Do you offer designing service for us?

A: Yes, we could design full solution drawings as your requirements. By using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (Xsteel) etc., we can design complex industrial building like office mansion, super marker, auto dealer shop,shipping mall, 5 stars hotel.

Q7: What is the delivery time?

A: Delivery time depends on order quantities. In general, the delivery time to nearest seaport in China will be 30 days after receiving deposit.

Q8: How can you get a quotation for your projects?

A: You can contact us by email, phone, Alibaba TM, WhatsApp, Skype, Viber and so on 24*7 and you will get reply within 8 hours.

Q9: How to ensure the product you supply is what we want exactly?

A: Before placing order, our sales and engineers' team will provide you the suitable solution according to your requirements.Proposal drawing, 3D drawing, Materials' photos, finished projects photos are available, which will help you understand the solution we provided deeply.

推薦されたプロダクト